Products

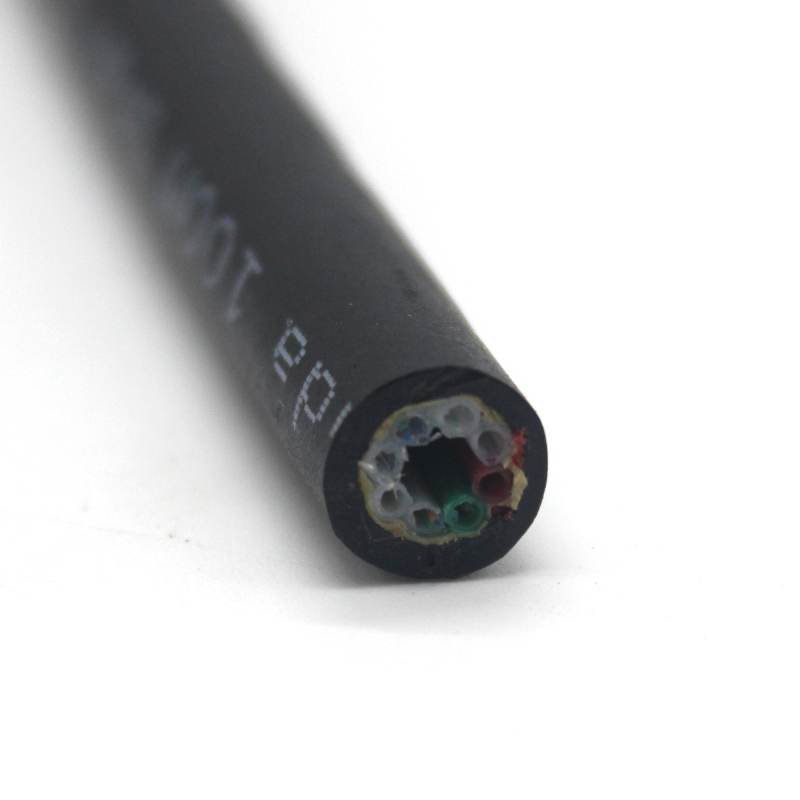

All Dielectric Self Supporting Fiber Optic Cable G652D ADSS Fiber Optic Cable

We are happy to answer any questions, please send your questions and orders.

Photos

Parameters

| Product name | ADSS Double PE Fiber Optic Cable |

| Fiber count | 24 cores |

| Construction | loose tube |

| Fiber type | Single mode |

| Outer jacket material | PE doubles |

| Jacket color | Negro |

| Wire diameter | 11,5 mm ± 0,5 mm |

| Weight | 100 KILOGRAMS / KILOMETER |

| Core Strength Mem | FRP |

| Application | Antenna and Duct |

| Warp radio | 10D/20D (millimeter) |

| Sample status | We can provide free sample |

Product Introduction

ADSS cable is a braided loose tube. The fibers, 250 μm, are placed in a loose tube made of high modulus plastics. The tubes are filled with a water resistant filling compound. The tubes (and fillers) are braided around an FRP (Fiber Reinforced Plastic) as a central non-metallic strength element in a compact, circular cable core. After the cable core is filled with filling compound. It is covered with a thin PE (polyethylene) inner sheath. After applying a braided layer of aramid yarns on the inner sheath as a reinforcing element, the cable is completed with a PE or AT (anti-tracking) outer sheath.

The actual condition of overhead power lines is taken into account when designing ADSS cable. For overhead power lines less than 110 kV, PE outer sheath is applied. FOR power lines equal to or greater than 110 kV, an outer cover is applied. The dedicated design of aramid quantity and braiding process can meet the demand in various spans.

Characteristics

1.Good mechanical and temperature performance.

2.High strength loose tube that is resistant to hydrolysis

3.Special tube filling compound ensures critical fiber protection

4.Crush resistance and flexibility

5.The following measures are taken to ensure the tightness of the cable:

6. Single fiber reinforced plastic as core strength member

7. Loose tube fill compound

8. 100% cable core filling

Applications

1. Adopted for outdoor aerial self-supporting installation

2. Long distance communication, local trunk line, CATV and computer networking system, telecommunications or outside plant campus backbone network

3. Ethernet LAN network, CCTV, network camera, PLC

4. Mechanically robust cable design for: Antenna, conduit

Product Categories

-

Phone

-

E-mail

-

Whatsapp

Whatsapp

-

skype

skype

-

WeChat

Judy

-

Top

Send us your information:

X-

Mr Herry

Phone/Wechat/Whatsapp:+8618123897029

Skype:sales09@aixton.com

-

Mr James

Phone/Wechat/Whatsapp:+8618566291592

Skype:aixton05