Products

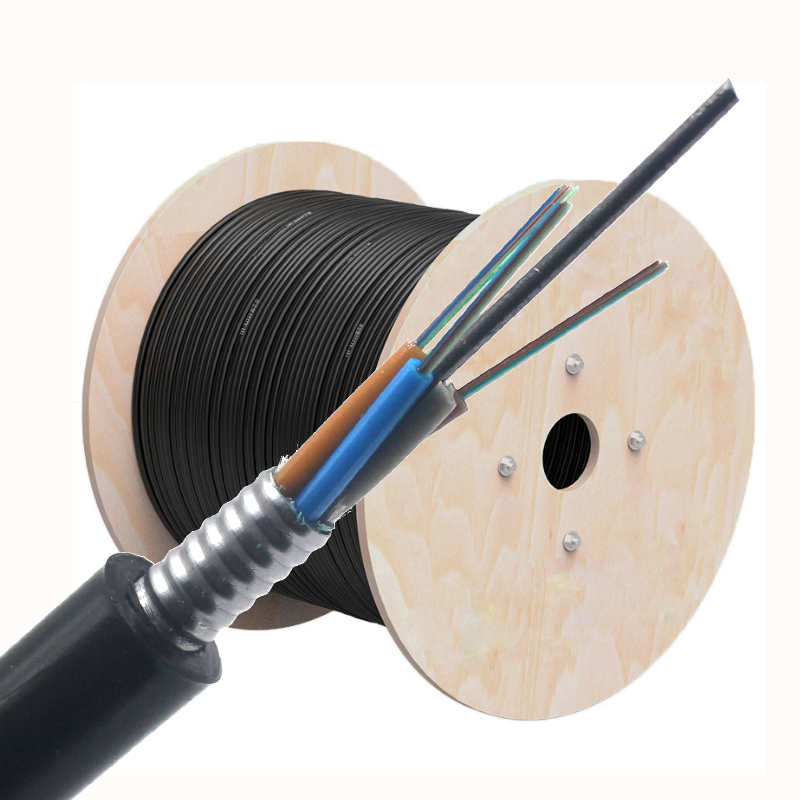

Outdoor underground fiber optic cable GYTS GYTA GYTA53 G652D armored fiber optic cable

We are happy to answer any questions, please send your questions and orders.

Photos

Parameters

| No. | Elements | Unit | Specification | |

| G.652D | ||||

| 1 | Liner diameter | μm | 125±0.7 | |

| 2 | Core cladding concentricity | μm | ≤0.5 | |

| 3 | Non-circularity of the coating | % | ≤0.7 | |

| 4 | Liner diameter | μm | 245±5 | |

| 5 | Coating-concentricity coating | μm |

| |

| 6 | Mode field diameter | 1310nm | μm | 9.2±0.4 |

| 1550nm | μm | 10.4±0.5 | ||

| 7 | Fiber cutting wavelength | nm | λcc≤1260 | |

| 8 | Attenuation (max.) | 1310nm | dB/km | ≤0.4 |

| 1550nm | ≤0.3 | |||

DETAIL

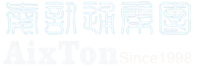

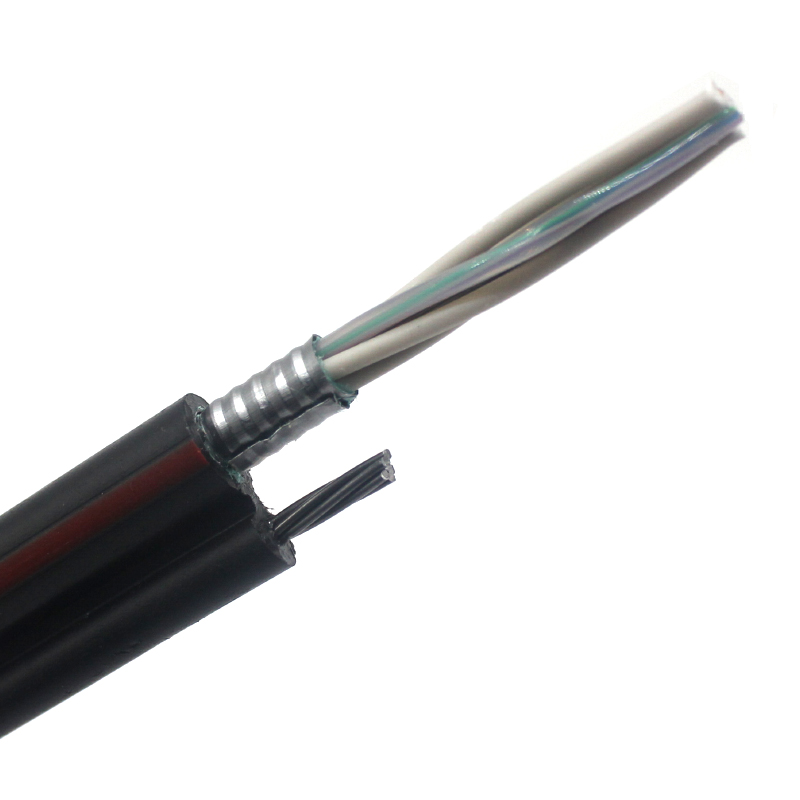

The fibers, 250 µm, are placed in a loose high modulus plastic tube.

The tubes are filled with a water resistant filling compound.

A steel wire, sometimes coated with polyethylene (PE) for high fiber count cables, is located in the center of the core as a metallic strength member.

The tubes (and fillers) are braided around the reinforcing member into a compact, circular cable core.

An aluminum polyethylene laminate (APL) is applied around the cable core, which is filled with the filling compound to

protect it from water ingress.

Then the cable core is covered with a thin PE inner sheath.

After the PSP is applied longitudinally over the inner sheath, the cable is completed with a PE outer sheath.

Characteristics

1.Good mechanical and temperature performance.

2.High strength loose tube that is resistant to hydrolysis

3.Special tube filling compound ensures critical fiber protection

4.Crush resistance and flexibility

5. The following measures are taken to ensure the tightness of the cable:

— Steel wire used as central strength member

—Loose tube fill compound

— 100% cable core filling

— APL Moisture Barrier

— PSP improving moisture proof

— Water blocking material

Applications

Adopted for outdoor distribution fiber optic cable system.

Suitable for air duct pipes, direct buried installation for mooring menthod

Local and long distance network (LAN) communication system.

Product Categories

-

Phone

-

E-mail

-

Whatsapp

Whatsapp

-

skype

skype

-

WeChat

Judy

-

Top

Send us your information:

X-

Mr Herry

Phone/Wechat/Whatsapp:+8618123897029

Skype:sales09@aixton.com

-

Mr James

Phone/Wechat/Whatsapp:+8618566291592

Skype:aixton05