Products

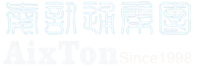

Outdoor Fiber Optic Cable Armored Steel Cable GYTS33 Submarine Submarine Cable

We are happy to answer any questions, please send your questions and orders.

Photos

Parameters

| Fiber count | 2~30 | 32~36 | 38~60 | 62~72 | |

| Item number | 6 | 6 | 5 | 6 | |

| Max. cores in tube | 6 | 6 | 12 | 12 | |

| Inner sheath diameter | 8.3 | 8.8 | 9.1 | 9.7 | |

| Steel wire diameter and No. | F1.0/28+34 | F1.0/29+35 | F1.0/30+36 | F1.0/32+38 | |

| Cable diameter approx. | 16.7 | 17.2 | 17.5 | 18.1 | |

| Approximate weight. (kg/km) | 543 | 568 | 590 | 635 | |

| Tensile Strength (N) | Long-term | 10000 | |||

| Short term | 20000 | ||||

| Crushing resistance (N/100mm) | Long-term | 3000 | |||

| Short term | 5000 | ||||

| Radius of curvature (mm) | Static | ≥15 × wire diameter | |||

| Dynamic | ≥30 × cable diameter | ||||

| Operating temperature (℃) | -40 -- +60 | ||||

| Application | Underwater | ||||

Product Introduction

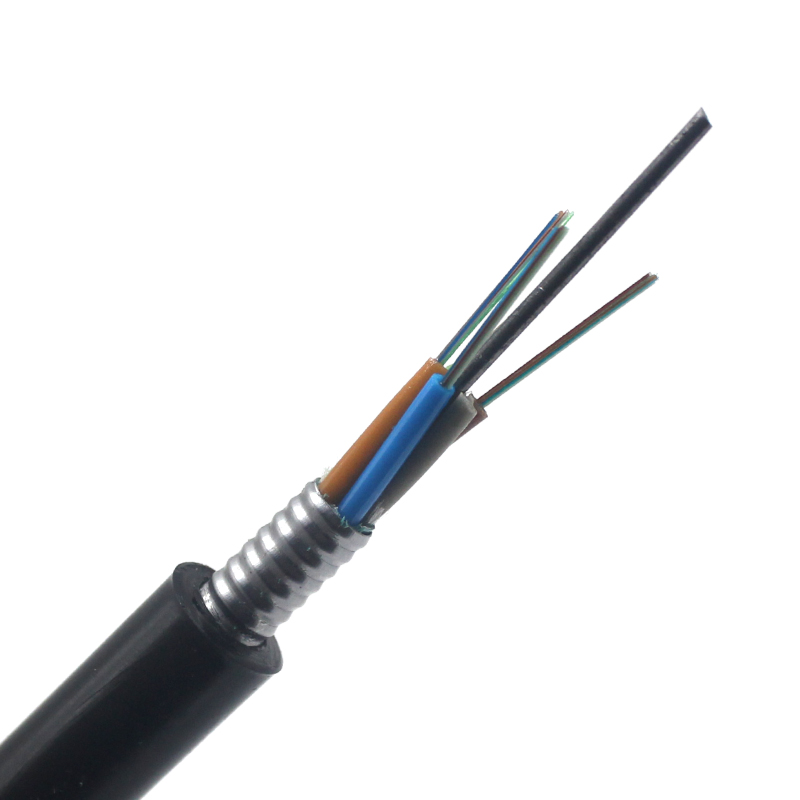

The structure of GYTS33 is placed with single-mode or multimode fibers in a loose tube made of a high modulus plastic filled with a waterproof compound. In the center of the cable there is a metal reinforcing member. For some cores of the optical cable, The metal reinforcing member must be extruded with a layer of polyethylene (PE). The tubes and fillers are braided around the strength member into a compact, circular cable core that is filled with the filler compound to protect it from the entry of water. onto the cable core to extrude a PE inner jacket. After being armored with double-row fine round steel wire, the outer polyethylene sheath is finally extruded to form the cable.

Characteristics

1. Submarine optical cable layer, direct buried, twisted, choose high quality optical fiber, make sure the cable has excellent transmission performance.

2. Precise control of fiber length, ensure the cable has excellent mechanical and temperature properties.

3. Full section waterproof structure ensures good water resistance and moisture-proof performance.

4. Special gelatin filled with the tube which plays a key role in protecting the fiber.

5. Corrosion-resistant phosphated steel wire with high strength modulus is used for the central reinforcing member.

6. Double-sided coated corrugated steel tape longitudinal shielding, double-layer steel wire wrapped shielding, ensure that the mechanical compression of the cable, bulletproof, meets the requirements of underwater placement.

7. Strict process, raw material control, ensures stable cable work for more than 30 years.

Applications

Suitable for inter-office and toll communication.

It is applied under water and placed directly underground.

Product Categories

-

Phone

-

E-mail

-

Whatsapp

Whatsapp

-

skype

skype

-

WeChat

Judy

-

Top

Send us your information:

X-

Mr Herry

Phone/Wechat/Whatsapp:+8618123897029

Skype:sales09@aixton.com

-

Mr James

Phone/Wechat/Whatsapp:+8618566291592

Skype:aixton05